Concept Exploration

Design Development

direction 1 direction 2

Finalized design of chosen direction

3D Set Render

Using Fusion 360, I created scale models of the final design direction. During the modeling process, I might make some changes to the designs, namely, each piece has three-fold symmetry, allowing each piece to have the correct profile no matter the orientation it's placed with.

MOLDING/CASTING PROCESS

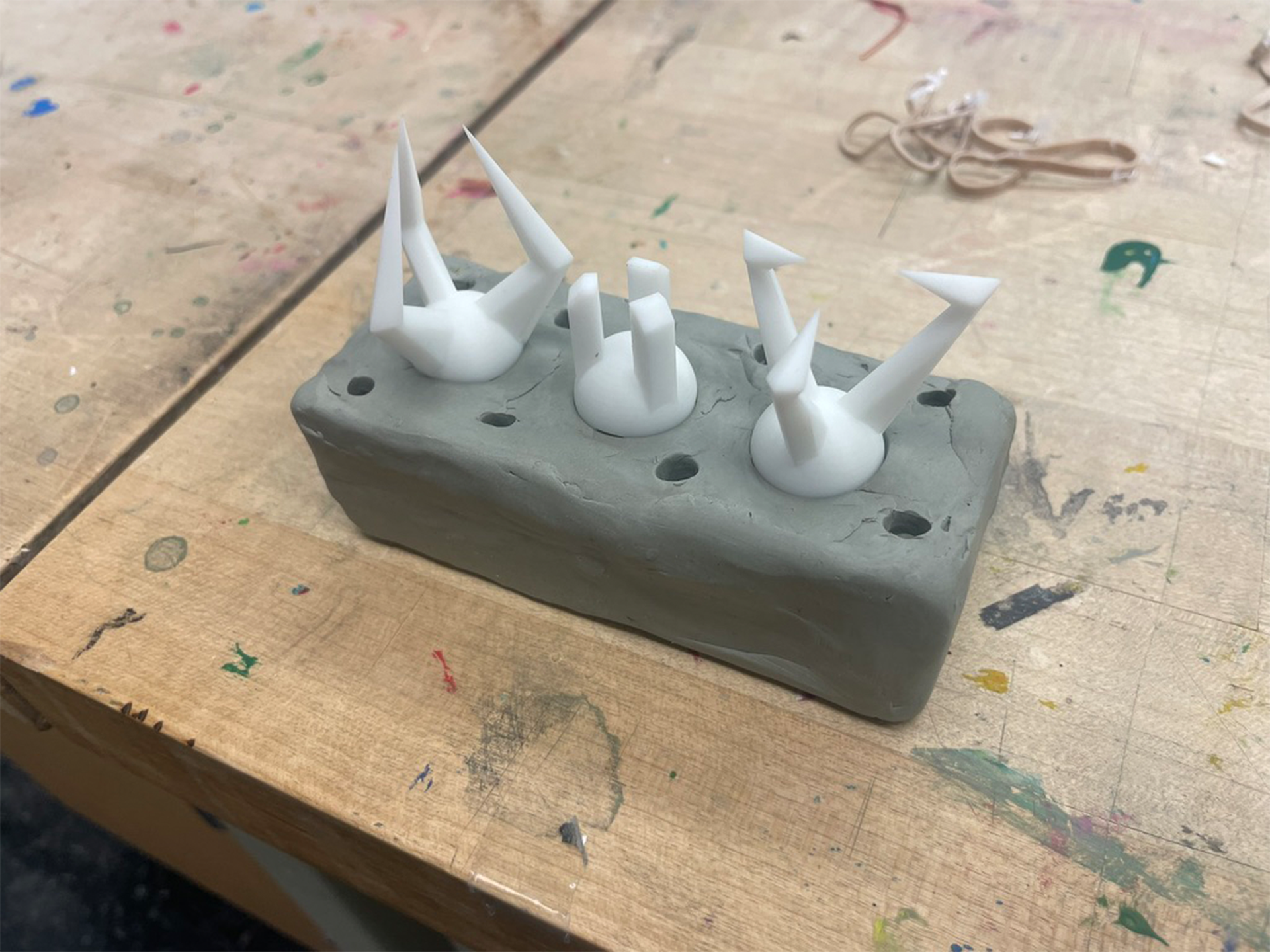

Using resin 3d printing, I created high-quality versions of each piece. I proceeded to use these high-quality models to create multiple 2-part molds using Oommoo. Finally, I weighed out, mixed, and cast each piece multiple times with a quick-cast resin poured in the molds to create a large number of parts.

Resin printed tops

resin prints in clay

set up 2nd half of mold

pour mold mixture

clean up both sides of mold

cast resin

casted legs

casted tops

FINAL PRODUCT